Fitted and mounted side hull flaps

%20zamontowane%20na%20gotowo.webp)

The "Kruk" Project – status as of early 2026 – Part VIII

Project PZL 106 "Raven"

Everything is going according to plan.

Welcome to 2026. Will this be the year when the project is completed? It seems so. We are getting closer and closer. As usual, we return to the history of the aircraft and review the progress of the project, which is already clearly visible.

Total production did not exceed 275 units. Production summary:

- PZL-106 - prototypes and information series - 15 units,

- PZL-106A - prototypes and serial A, AR, and AS - 130 units (including approx. PZL-10610 AS),

- PZL-106AT - prototype - 1 unit,

- PZL106B - prototypes and serial B, BR, and BS - 75 units (including approx. 12 BS and approx. 25 BR),

- PZL-106BT - prototypes and serial - 50 units,

- PZL-106BTU - prototype - 1 unit

Total - 273 units

Half of the production went to East Germany, approx. 50 units to ZUA (Agricultural Aviation Services), and the rest was purchased by individual users, including those from Czechoslovakia, Egypt, Hungary, Argentina, and Spain. On January 1, 2007, there were 10 PZL-106 "Kruk" aircraft in the Polish aircraft register, including: Agricultural Aviation Services Plant - 8 units, available - 2 units.

Single-seat or two-seat low-wing strut-braced aircraft with metal construction.

Rectangular wing, NACA 2415 profile, 4° dihedral, 6° sweep, 6°06' wedge angle. Two-piece, twin-spar, semi-monocoque, all-metal construction. Integral fuel tanks in the inter-spar caisson. The wings are connected to the fuselage by hinged fittings at the ends of the spars and V-shaped struts attached to the front spar. Fixed segmented slots across the entire span. Mass- and aerodynamically balanced ailerons and slotted flaps. Ailerons and flaps are of metal skeleton construction, covered with fabric. Wing tips are made of glass-epoxy composite.

Rectangular cross-section fuselage. Lattice structure, welded from steel tubes, front lattice bulkhead housing a chemical tank reinforced with wing struts - force circulation closure through the wing. Removable fuselage coverings, mounted with quick-release fasteners. Glass-epoxy composite spacers in the front, duralumin covers on the rear and bottom of the fuselage. The crew cabin is a separate unit attached to the truss. Its structure is designed to withstand heavy loads in the event of an emergency landing or crash (up to 40 g). The cabin is sealed, heated, and ventilated, with a constant low pressure maintained inside. Behind the pilot's cabin is a space for a mechanic. The firewall is made of titanium sheet metal.

Classic tailplane, trapezoidal tailplane contours, slightly slanted vertical tailplane. Metal stabilizers, double-girder, supported by struts with a slight rise. Rudder construction - metal frame, fabric covering. Vertical tailplane enlarged by adding an extension to the vertical stabilizer. Classic fixed landing gear. Continued in the next entry...

Let's take a look at the progress of the project, i.e., a set of photos from Henryk Wickie's workshop.

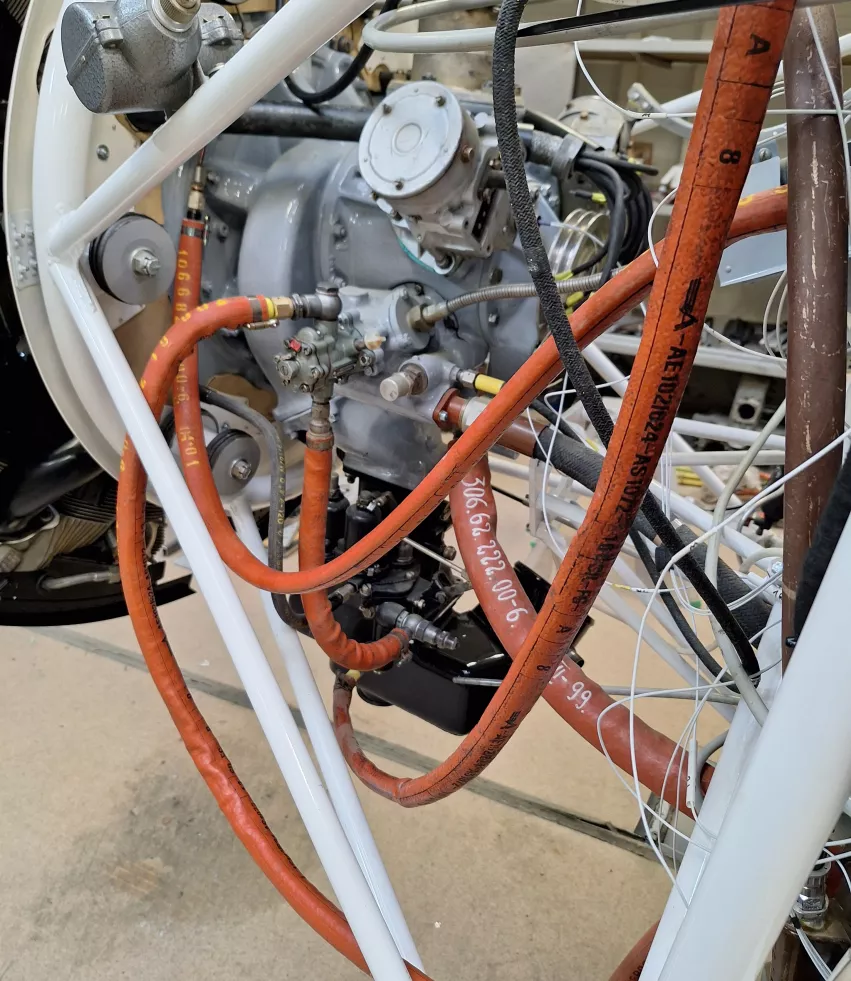

Rubber hoses for oil and fuel systems, complete set

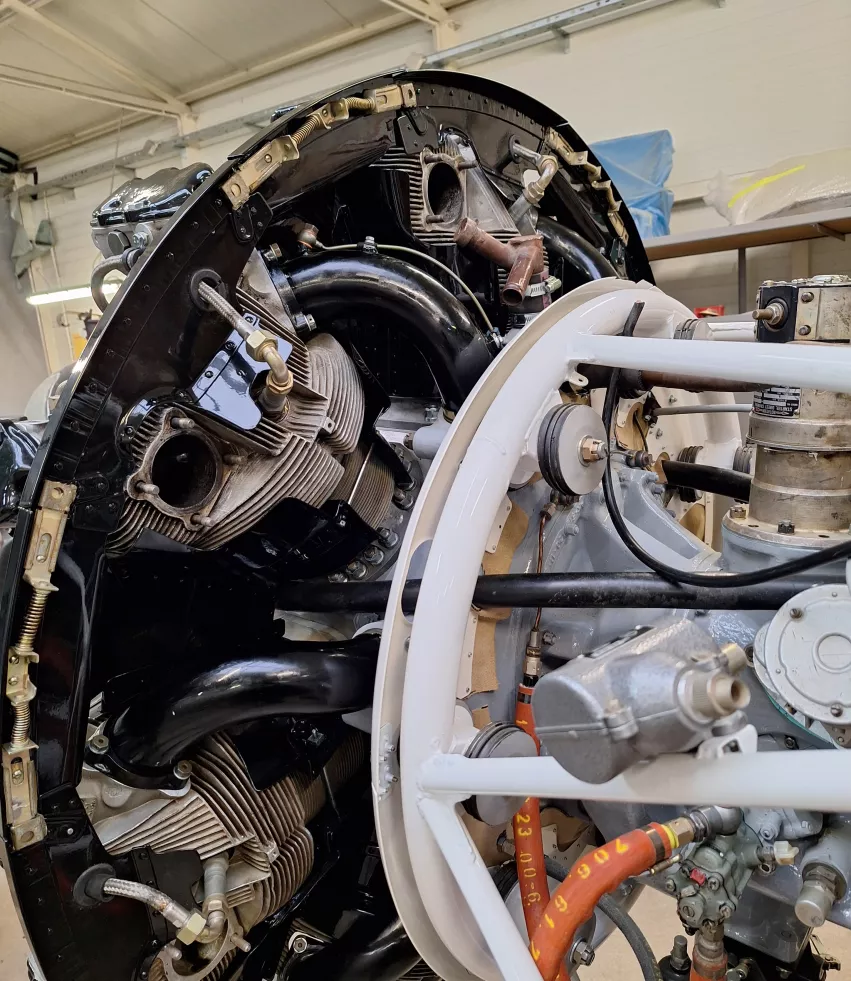

Installed suction pipes and engine injection manifold

Left wing fuel tank ready for closure

Left wing repaired and ready for painting—top view

Right wing repaired and ready for painting—view from below

Partition in the mechanic's cabin - view from the seat

Partition in the mechanic's cabin ready for covering - rear view

Riveted right wing fuselage skins. Leading edge and trailing edge skins made new along the entire length of the wing.

Lower fuel tank cover assembly ready for installation on the wing